Unlocking Excellence in Metal Fabrication: Your Trusted Partner as a China Precision CNC Turning Parts Factory

In the competitive landscape of modern manufacturing, precision, quality, and efficiency are the cornerstones of success. For businesses seeking a reliable metal fabricator capable of delivering high-precision components, partnering with a dedicated china precision cnc turning parts factory becomes essential. At deepmould.net, we stand out as a leading metal fabricator specializing in precision CNC turning that meets the most rigorous standards in the industry.

The Role of a China Precision CNC Turning Parts Factory in Modern Manufacturing

Today’s manufacturing environment demands highly accurate, cost-effective, and rapid turnaround solutions, particularly in the production of complex metal components. A china precision cnc turning parts factory serves as a strategic partner for diverse industries, including aerospace, automotive, medical devices, electronics, and industrial machinery.

These factories focus on customized manufacturing processes, leveraging advanced CNC technology to create parts with exceptional precision and repeatability. The role goes beyond simple machining; it involves integrated engineering solutions, quality assurance, and supply chain management to ensure our clients' competitiveness and innovation.

Why Choose deepmould.net for Your Metal Fabrication Needs?

1. Unmatched Expertise in Precision CNC Machining

- Our team combines decades of experience in metal turning, milling, and pairing multiple machining processes for complex designs.

- We specialize in manufacturing small to large batch production runs with tight tolerances (up to ±0.005 mm).

- Continuous investment in state-of-the-art CNC machines ensures adherence to international standards.

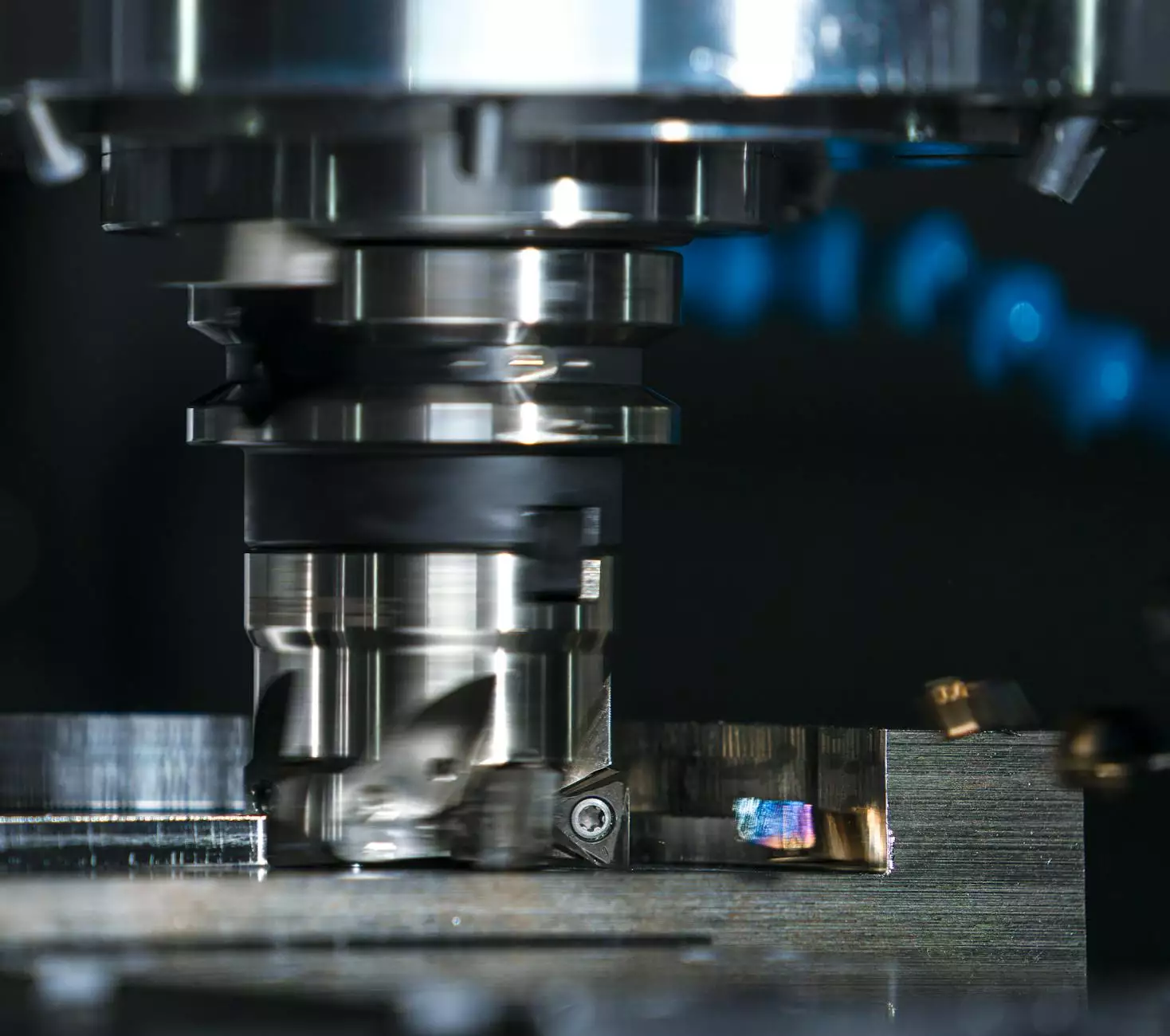

2. Advanced Technology and Equipment

- Utilization of multiaxis CNC lathes, high-speed spindles, and automatic tool changers enables multi-faceted machining in a single setup.

- In-house 3D CAD/CAM software allows for precise programming and simulation before production, reducing errors and waste.

3. Comprehensive Quality Assurance

- Rigorous inspection procedures, including coordinate measuring machines (CMM), surface roughness testers, and material testing.

- Achieving ISO 9001 and industry-specific certifications to guarantee consistent quality and traceability.

4. Customization and Flexibility

- Capability to handle diverse materials such as stainless steel, titanium, aluminum, brass, and engineering plastics.

- Offering tailored solutions to meet unique design specifications and rapid prototyping requirements.

Key Industries Benefiting from Precision CNC Turning Parts

The diversity of industries requiring high-precision turned parts underlines the importance of a skilled china precision cnc turning parts factory. Here are some major sectors we serve:

Aerospace Industry

Aircraft components demand extreme precision, reliable material properties, and adherence to strict safety standards. Our CNC turning capabilities enable us to produce complex engine components, landing gear parts, and instrumentation hardware with consistent quality.

Automotive Sector

From transmission parts to engine components, precision turned parts are vital for performance and durability. Our facilities ensure high-volume output with tight tolerances necessary for modern vehicles.

Medical Devices

The medical industry requires biocompatible materials and ultra-precise machining for surgical instruments, implants, and diagnostic equipment. We prioritize cleanroom practices and validation to meet these requirements.

Electronics and Semiconductor Manufacturing

Miniaturization in electronics demands micron-level accuracy. Our CNC turning solutions cater to manufacturing tiny, complex components essential for circuitry and connectors.

The Manufacturing Process at a Leading China Precision CNC Turning Parts Factory

1. Design and Engineering

Our process begins with comprehensive understanding of client specifications, followed by detailed CAD models and engineering drawings. We offer consultative advice to optimize design for manufacturability and cost efficiency.

2. Material Selection

Choosing the right material is crucial for performance and longevity. We guide clients in selecting suitable metals or plastics based on application demands, environmental factors, and budget considerations.

3. Precision Machining

Using multi-axis CNC lathes, we produce high-precision parts through turning, boring, and threading processes. Our machines support complex geometries and tight tolerances to ensure functionalities are met or exceeded.

4. Inspection and Quality Control

Every batch undergoes strict quality checks utilizing CMM, laser scanners, and surface analysis. We maintain traceability records for full transparency and compliance.

5. Surface Finishing and Coating

Optional surface treatments like anodizing, plating, or polishing enhance corrosion resistance, wear durability, and visual appeal.

6. Packaging and Delivery

Products are packaged to prevent damage during transit, with options for custom branding and logistics support. We emphasize timely delivery as part of our dedicated service.

Advantages of Working with a China Precision CNC Turning Parts Factory

Cost Efficiency and Competitive Pricing

Due to China's cost-effective manufacturing environment, we provide premium quality components at a fraction of the price compared to Western counterparts, enabling our clients to maximize profitability.

Fast Turnaround with High Productivity

Our large-scale manufacturing infrastructure supports quick response times and rapid prototyping, helping clients accelerate their product development cycles.

Access to Cutting-Edge Technology

Global investment in advanced CNC machinery ensures that our factory remains at the forefront of technological innovation, enabling us to meet the most demanding specifications.

Streamlined Supply Chain Management

Our integrated logistics network guarantees timely delivery, inventory flexibility, and cost control, making us a reliable partner in your manufacturing journey.

The Future of Metal Fabrication and Role of China as a Manufacturing Powerhouse

The landscape of metal fabrication and precision machining is evolving rapidly, driven by innovations in automation, artificial intelligence, and material science. China continues to solidify its position as a global leader in manufacturing, offering comprehensive solutions that combine cost-effectiveness with technological excellence.

As a dedicated china precision cnc turning parts factory, deepmould.net remains committed to excellence, customer satisfaction, and continuous innovation. We aim to not only meet but exceed industry standards, ensuring that our clients stay ahead in their markets.

How to Partner with deepmould.net for Your Metal Fabrication Needs

Engaging with us involves a straightforward process designed to align with your project goals:

- Reach out with your design files and specifications.

- Receive professional consultation and cost estimate. 3>Approve the plan and initiate your project. 3>Our team executes precision machining, with continuous communication and quality checkpoints. 4>Get your finished parts, backed by full quality documentation.

Our dedication is to provide superior quality components, timely delivery, and excellent customer service—making us your preferred china precision cnc turning parts factory.

Conclusion: Empower Your Business with Top-Quality Precision CNC Turned Metal Parts

Choosing the right partner for metal fabrication can significantly influence your product’s performance, cost, and time-to-market. As a prominent deepmould.net and a specialized china precision cnc turning parts factory, we leverage cutting-edge technology, unwavering quality standards, and industry expertise to deliver customized metal components that transform your ideas into reality.

Embrace the potential of advanced manufacturing—partner with a factory committed to innovation, quality, and customer success. Contact us today to discover how we can help elevate your business through precision, reliability, and excellence in metal fabrication.