Understanding Lifting Regulations in Business: A Comprehensive Guide to Safe and Compliant Operations

In the modern industrial and commercial landscape, the importance of adhering to lifting regulations cannot be overstated. Whether you operate within the realm of home & garden, employ skilled gardeners, or engage in pest control services, understanding and implementing proper lifting practices is essential for ensuring safety, compliance, and operational efficiency. At SafePlant UK, we recognize that robust lifting protocols are the backbone of accident prevention and productivity enhancement in diverse business sectors.

Why Are Lifting Regulations Crucial for Businesses?

Lifting regulations are established guidelines and legal requirements designed to prevent injuries and accidents associated with manual and mechanical lifting tasks. Proper compliance not only safeguards workers but also minimizes costly downtime, legal liabilities, and damage to equipment or property. For businesses involved in activities such as gardening, pest control, or general maintenance, strict adherence to these regulations sustains operational integrity and promotes a safety-first culture.

Key Benefits of Complying with Lifting Regulations

- Enhanced Worker Safety: Reducing the risk of musculoskeletal injuries and accidents.

- Legal Compliance: Avoiding legal penalties and ensuring adherence to health and safety laws.

- Operational Efficiency: Streamlining lifting processes to optimize productivity.

- Damage Prevention: Protecting equipment, products, and infrastructure from mishandling.

- Reputation Management: Building trust with clients through commitment to safety standards.

The Scope of Lifting Regulations in Business Operations

Lifting regulations encompass a broad spectrum of standards that govern how physical loads are handled, transported, and stored across various industries. These include legal frameworks, best practices, and safety protocols mandated by government agencies such as the Health and Safety Executive (HSE) in the UK, along with international standards.

Primary Elements Covered by Lifting Regulations

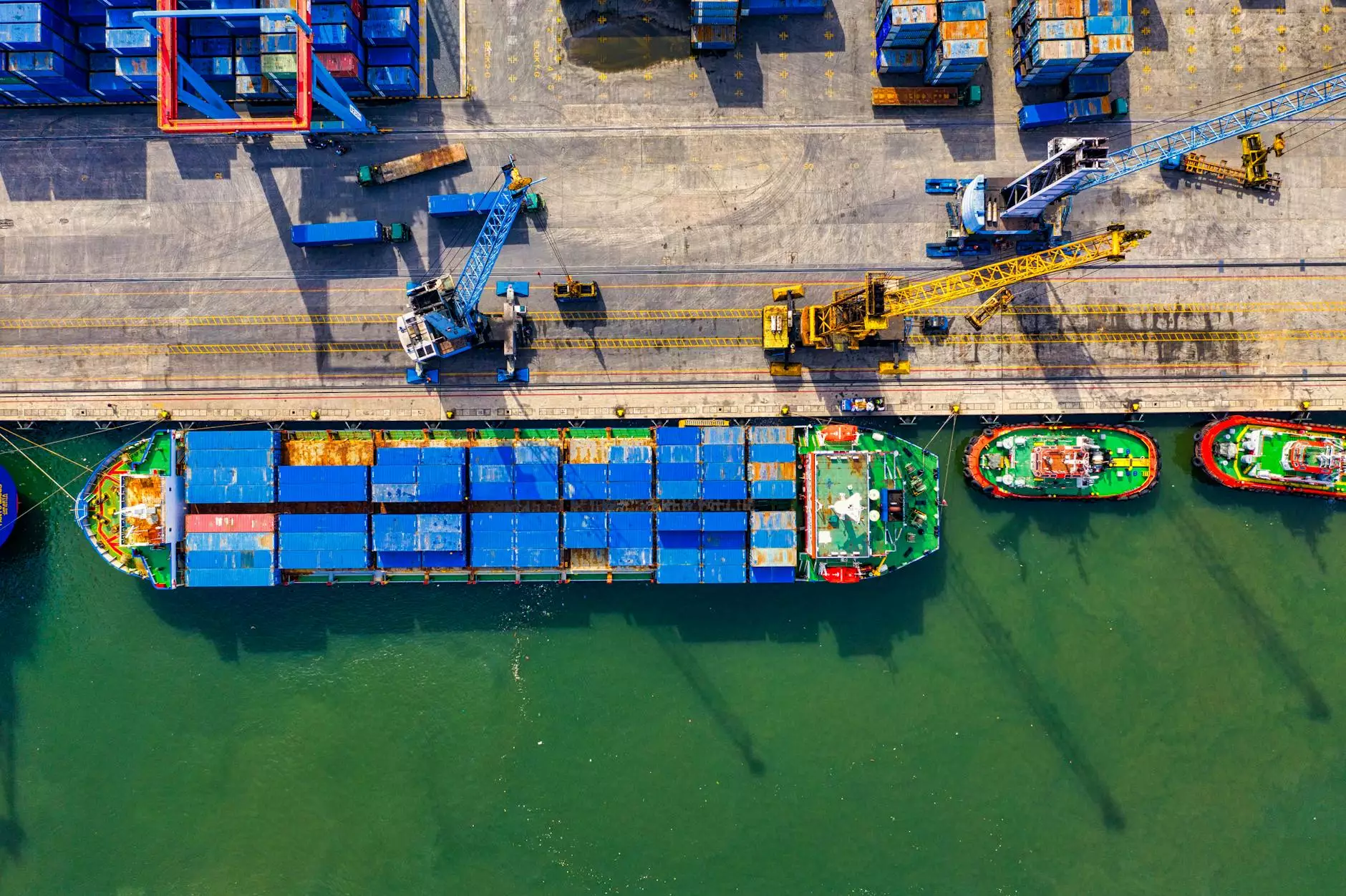

- Mechanical Lifting Equipment: Use of cranes, hoists, forklifts, and lifting machinery that must meet safety standards.

- Manual Handling: Safe lifting techniques and ergonomic practices for manual loads.

- Load Assessment and Planning: Proper evaluation of load weight, shape, and center of gravity before lifting.

- Training and Competency: Ensuring employees are well-trained in safe lifting procedures.

- Inspection and Maintenance: Regular checks and upkeep of lifting equipment to prevent failure.

- Risk Assessment: Identifying potential hazards associated with lifting tasks and implementing mitigation measures.

Implementing Lifting Regulations in Your Business

Adopting a comprehensive approach to lifting regulations involves multiple steps that ensure safety and compliance are embedded into everyday operations. Here's how your business can effectively implement these standards:

1. Conduct a Thorough Risk Assessment

Begin with identifying all lifting tasks involved in your business activities, including those that might seem routine, such as moving gardening supplies or pest control equipment. Recognize potential hazards, such as unstable loads, awkward postures, or inadequate equipment. This initial step is crucial in establishing a foundation for safe practices.

2. Invest in Proper Equipment and Tools

Ensure that all lifting machinery complies with industry safety standards. For gardening or pest control businesses, this might include lightweight hoists, ergonomic trolleys, and manual handling aids. Regular inspections, certifications, and maintenance routines are vital to keep equipment in optimal condition and prevent failure during operations.

3. Provide Comprehensive Training

Employees should be equipped with knowledge of correct lifting techniques, such as bending with the knees, maintaining a stable base, and avoiding twisting the torso. Training should also cover the use of mechanical aids and recognizing load limits. A well-trained workforce significantly reduces the risk of injuries and enhances overall safety.

4. Develop Clear Safety Protocols and Procedures

Formalize procedures for lifting tasks, including load assessments, communication signals, and emergency response plans. Display clear signage and procedural guides at workplaces to reinforce safe practices. Regular refresher training sessions help maintain high safety standards.

5. Foster a Safety-First Culture

Promote awareness among staff about the importance of adherence to lifting regulations. Encourage reporting of hazards and near-misses, providing feedback and incentives for safe behavior. A proactive safety culture reduces incidents and cultivates accountability.

Special Considerations for Small Business and Gardeners

Many small businesses and gardening services may believe that lifting regulations primarily pertain to large industrial operations. However, safety principles are universal. Practices such as proper lifting posture, using appropriate tools, and avoiding overexertion are equally critical regardless of business size. Implementing these simple yet effective strategies can dramatically improve safety and efficiency in everyday activities.

Innovative Technologies and Lifting Solutions

The evolution of technology offers innovative solutions to enhance compliance with lifting regulations. From lightweight ergonomic tools to automated lifting systems, modern equipment helps reduce manual strain and potential errors. For example, compact electric hoists can facilitate lifting heavy garden materials with minimal physical effort, ensuring both safety and productivity. Utilizing such technologies aligns with industry best practices and supports sustainable business growth.

The Legal Framework Surrounding Lifting Regulations in the UK

In the United Kingdom, lifting regulations are primarily governed by the Health and Safety at Work Act 1974, along with specific regulations such as the Provision and Use of Work Equipment Regulations 1998 (PUWER) and the Lifting Operations and Lifting Equipment Regulations 1998 (LOLER). These laws mandate employers to conduct risk assessments, maintain equipment, and provide training. Non-compliance can lead to severe penalties, including fines and legal action, emphasizing the importance of adhering to the law for all business operators.

Supporting Your Business with Expert Guidance from SafePlant UK

At SafePlant UK, we offer comprehensive consultancy and services to ensure your business complies with all lifting regulations. Our expertise includes:

- Site Assessments: Evaluating your current lifting operations and identifying areas for improvement.

- Equipment Supply and Certification: Providing high-quality lifting gear with certification to meet legal standards.

- Training Programs: Delivering tailored courses on safe manual handling and machinery operation.

- Maintenance and Inspection Services: Regular checks to uphold safety standards and extend equipment lifespan.

- Emergency Planning: Developing response strategies for lifting-related incidents to minimize impact.

Conclusion: Prioritizing Safety through Effective Lifting Regulations

In conclusion, understanding and implementing lifting regulations is a fundamental aspect of responsible business management. Whether managing a gardening service, pest control operation, or other small to medium enterprise, maintaining safe lifting practices fosters a safer working environment, enhances productivity, and ensures legal compliance. Investing in proper equipment, employee training, and adherence to legal standards will significantly benefit your business in the long term.

Partner with SafePlant UK today to access expert guidance and innovative solutions that help embed safety at the core of your business operations, aligned with all lifting regulations.